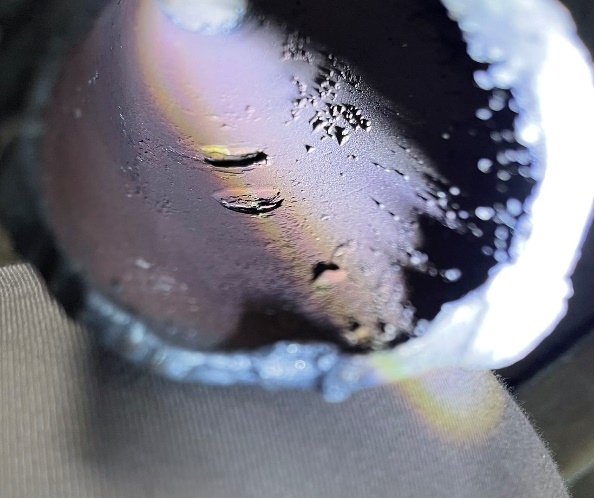

For the four-tube inspection of boilers, including water-cooled wall tubes, superheater tubes, reheater tubes, economizer tubes, and other boiler ancillary equipment pipelines, such as high and low pressure heater pipelines and primary air pipelines, boiler desuperheating water pipelines, etc. We have accumulated rich experience and cases in small-diameter pipelines and joints.

Traditional ultrasonic thickness measurement can only detect a spot-shaped area the size of a probe, and cannot find the corrosion and thinning defects of wall thickness in other parts of the pipeline, which is easy to miss.

The furnace tube scanning technology is surface scanning, which can comprehensively scan and detect the surface of the water-cooled wall pipeline. The wall thickness of the entire pipeline can be displayed through the algorithm image straight pipe, and the defect location and scope of the problem can be found, and the detection efficiency is high. Avoid missed detections and false detections that exist in other detection methods.

Precise positioning

On-site drawing, we can visually see the thinning of the wall thickness and the size of the location.

Face scan

The surface scanning efficiency is high, and the entire surface of the pipeline is detected to avoid missed inspections.

In-service detection

The pipeline can be tested under operation, and the working temperature is -30℃-500℃.

High precision

Detection error ±0.01mm.

Easy detection: no need for line grinding.

Pipe material:Ordinary carbon steel, stainless steel and alloy steel, etc.

Wall thickness range:0-40mm

Operating temperature:-30℃-500℃

Detection accuracy:±0.01mm

Detection of minimum pipe diameter:DN15

Detection speed:2m/min

Technical introduction