Wall thickness range:0-10mm

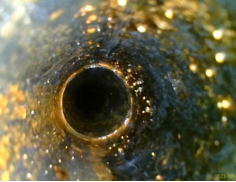

Adapt to pipe diameter:DN12mm-DN50mm

Detection speed:40 seconds/piece for ferromagnetic material, 20 seconds/piece for non-ferromagnetic material

Detectable defect types:Uniform thinning, local thinning, pitting defects, perforations, nicks, cracks, deformation defects

Strong detection ability

The detection blind area is small, and the defects inside, outside and near the baffle of the tube bundle can be detected.

Strong on-site adaptability

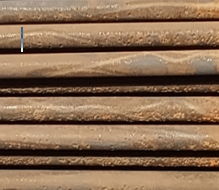

A small amount of rust, scale, and standing water will not affect normal detection.

Intuitive test results

The signal characteristic curve graph is used to directly reflect the detection result.

A lot of experience and tube bundle cases have been accumulated for on-site emergency detection of daily leakage cold exchange equipment, special detection of shutdown and shortage elimination, and large-scale cold exchange equipment scanning and inspection during the overhaul of petrochemical enterprises.

Contrasting far-field eddy currents

The signal quality of pulse eddy current is strong, which is 100-500 times that of far-field eddy current. It can be directly tested without making defective sample tubes before formal testing.

Contrast rotational ultrasound

Before the formal inspection, the pulsed eddy current does not need to add medium to the tube, and can detect crack defects that are not sensitive to rotating ultrasonic.

Technical introduction